Wherever Holes Are Drilled, Reliable Deburring is Essential

Swiss Precision Since 1961

Drilling inevitably creates burrs, which must be removed to ensure the functionality and quality of machined parts. Leading manufacturers across industries rely on HEULE Precision Tools to streamline deburring processes, improve efficiency, and maintain consistent results—whether in aerospace, automotive, energy, or general engineering applications.

Delivering Reliable Deburring in High-Volume Manufacturing

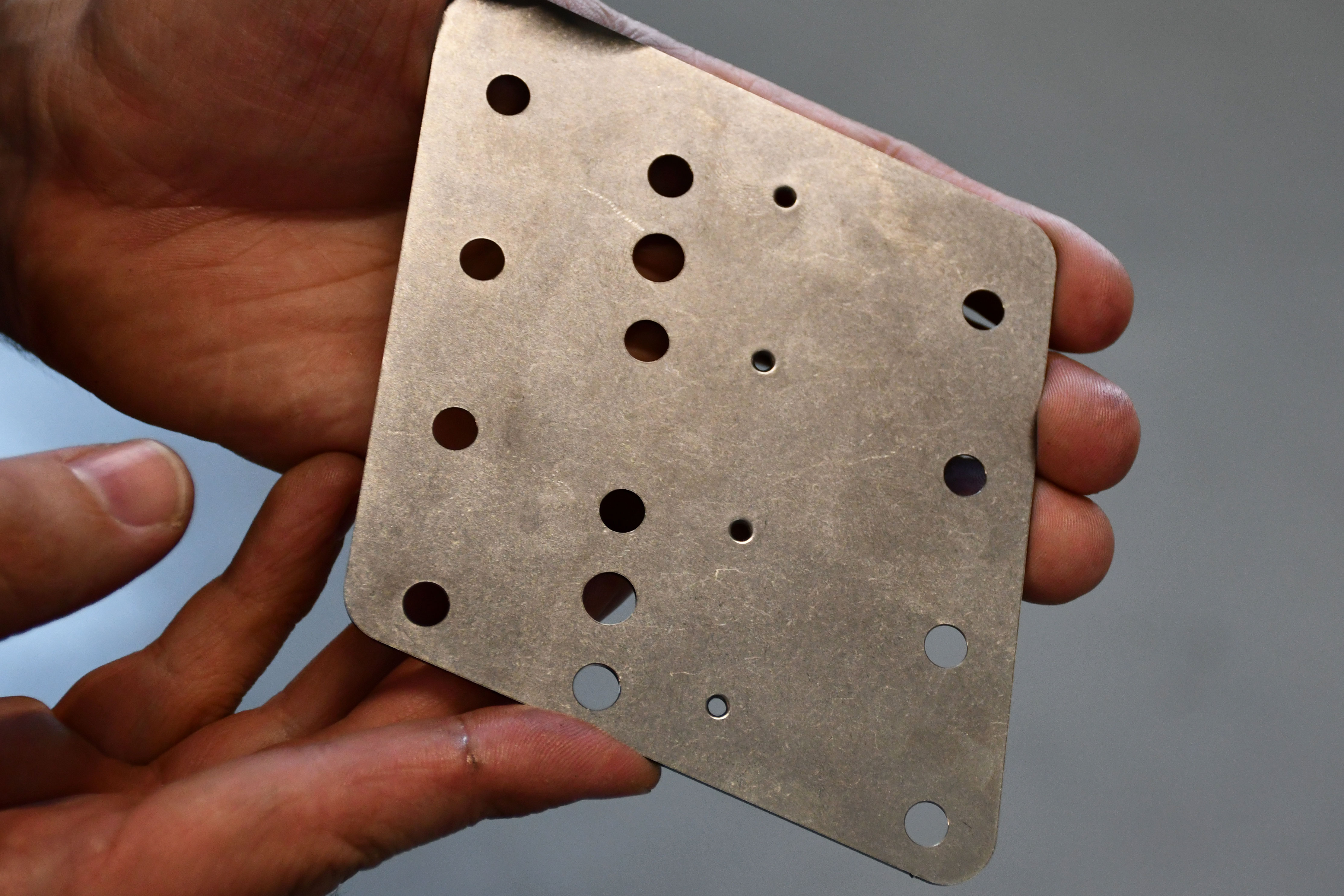

A global leader in textile machinery manufacturing recently integrated HEULE deburring tools into their production process. The challenge? Removing burrs from thousands of bores on precision stitch plates used in embroidery machines. These plates require smooth, burr-free holes to prevent thread breakage and ensure flawless operation.

By implementing the COFA deburring tool, they achieved complete burr removal on both entry and exit holes—fully automated within the machining process. This eliminated manual deburring, reduced cycle times, and ensured reliable results even in high-production environments.

"The programming is straightforward, and blade changes are easy—even for new operators. HEULE's tools are ideal for our apprentices and experienced machinists alike." – Production Manager, Textile Machinery Manufacturer

With HEULE’s COFA solutions, they now deburr over 300,000 bores per year, ensuring smooth operation for their customers worldwide.

Back Spotfacing: Enhancing Process Reliability

In another application, a customer producing cast components faced challenges with counterboring screw head recesses. Their previous back-spotfacing tool had a short service life, inconsistent results, and required complicated blade changes—leading to frequent downtime.

Switching to HEULE’s BSF back-spotfacing tool provided immediate benefits:

- Increased tool life with consistent performance

- Easy blade changes without requiring extensive training

- Improved efficiency by reliably producing counterbores with a 2.0x bore diameter ratio (and up to 2.3x if needed)

With this solution, they now machine over 12,000 counterbores annually, increasing both productivity and reliability.

Automating Chamfering for High-Volume Production

For manufacturers processing thousands of bores per year, HEULE’s SNAP chamfering tool provides an automated solution that eliminates the need for secondary operations. One of our customers produces over 200,000 bores annually in aluminum square tubes and previously relied on a slow, manual deburring process.

By implementing the SNAP tool, they now chamfer both the front and back edges in a single pass—without reversing the spindle or rotating the part. The carbide blade is also easily replaced by hand, minimizing downtime.

"The ability to deburr both sides of the hole in one pass without stopping production is a game-changer." – Production Engineer

Optimizing Your Machining Processes

Whether you’re dealing with back spotfacing, deburring, or chamfering, HEULE Precision Tools offers proven solutions that help manufacturers improve efficiency, reduce cycle times, and maintain superior part quality. Our tools are designed for seamless integration into CNC, transfer, and multi-spindle machines, making them the ideal choice for high-volume and precision machining applications.

Interested in optimizing your machining process? Contact us today to learn how HEULE Precision Tools can enhance your production efficiency.